Introduction to Thermal Power Company Cao Ngạn - TKV

Thermal Power Company Cao Ngạn (TKV) is a leading electricity generation enterprise utilizing fossil fuel, making significant contributions to the power supply in the region and ensuring the continuous and stable operation of the national electricity system. With its large scale and extensive operations, efficient management and monitoring of production equipment are crucial to ensure optimal operational performance.

Operational Logbook - A Solution for Monitoring Production Equipment Parameters

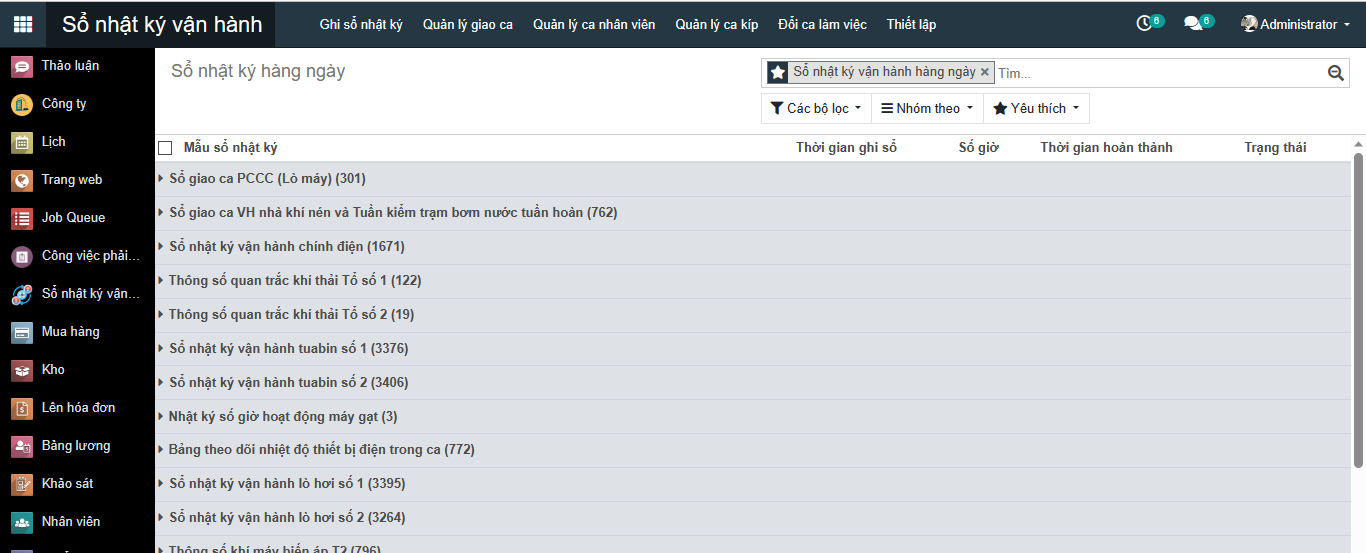

To enhance the quality of management and monitoring of production equipment operations, Thermal Power Company Cao Ngạn has implemented the Operational Logbook module, an advanced solution for tracking and recording the operational parameters of production equipment. The Operational Logbook offers outstanding features that optimize operational processes as follows:

1. Monitoring Production Equipment Parameters

The Operational Logbook allows employees to closely and accurately monitor the operational parameters of production equipment. Key parameters such as pressure, temperature, fluid flow rate, and other critical technical data are regularly recorded in the logbook. This enables the early detection of potential issues and timely intervention to prevent serious consequences.

2. Automated Recording of Equipment Parameters

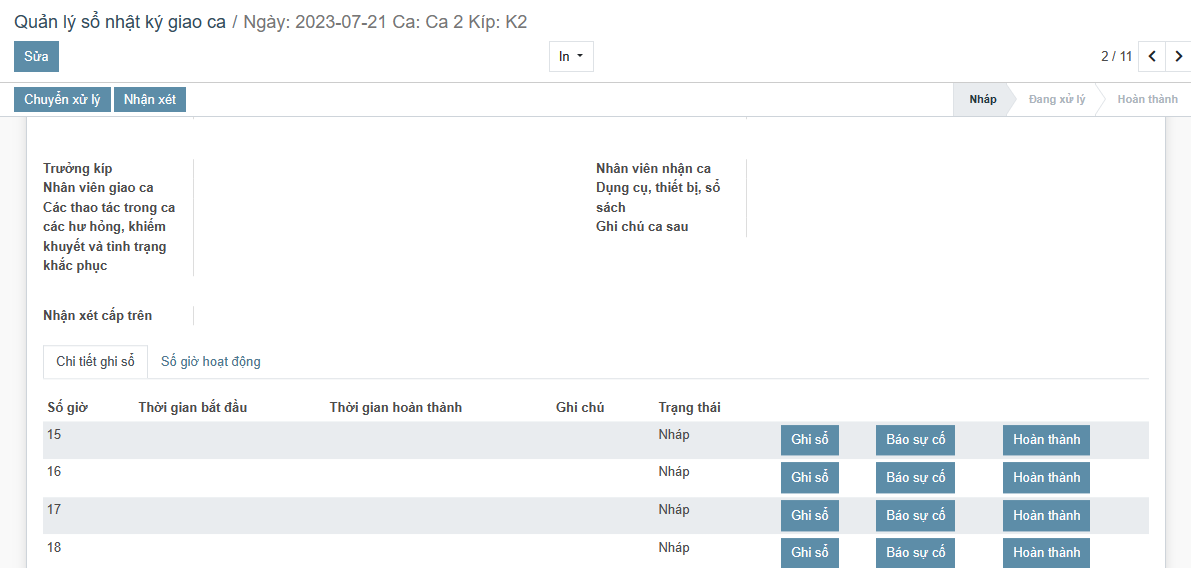

The Operational Logbook module enables the automated recording of equipment parameters within set intervals. Instead of manually recording data, the system automatically captures and logs the information, reducing human errors and saving valuable time for employees.

3. Timely Detection of Abnormal Equipment Operations

An important feature of the Operational Logbook is its ability to automatically detect abnormal operations of equipment. Utilizing artificial intelligence and continuous data collection, the system can identify irregular patterns in equipment operations. Employees receive immediate alerts, enabling them to intervene promptly and mitigate potential risks.

4. Digital Signatures, Replacing Manual Signatures

The Operational Logbook has transitioned traditional manual signatures into a digital environment. All parameters and data are securely stored and accessible remotely, allowing employees to view and approve information from anywhere without the need to be physically present at the equipment. This streamlines workflow processes and enhances flexibility for monitoring and management tasks.

5. Swift Review of Recorded Historical Data

The Operational Logbook module also offers the capability to quickly and conveniently review historical data that has been recorded in the past. This allows employees to compare data and analyze the operational efficiency of equipment over extended periods, enabling them to make informed decisions regarding technical matters and rational production strategies.

Other features of the Operational Logbook module include:

6. Smart Alert Integration:

The Operational Logbook is equipped with a smart alert system, enabling automatic and accurate detection of warning signs from production equipment. These alerts can be sent to important communication channels, such as email, text messages, or mobile applications, allowing employees to promptly identify issues and intervene when necessary.

7. Data Analysis Support:

The Operational Logbook provides intelligent data analysis capabilities, generating easy-to-understand reports and charts regarding the performance of equipment operations. Employees and management can access crucial figures and statistics, aiding them in making strategic decisions and improving production processes.

8. Remote Access Integration:

The Operational Logbook supports remote access integration, enabling employees to monitor and manage information remotely through mobile devices or personal computers. This optimizes project management and monitoring while enhancing flexibility and responsiveness to unexpected situations.

9. High-level Security Integration:

To ensure the safety of critical data, the Operational Logbook utilizes advanced security solutions. Information and data are encrypted and tightly protected, ensuring that only authorized personnel can access this essential information.

10. Easy Integration with Other Systems:

The Operational Logbook module is designed for seamless integration with other systems and applications within the enterprise. This streamlines workflow efficiency, minimizes disconnects, and ensures smooth data sharing and synchronization.

Conclusion:

The deployment of the Operational Logbook module has brought numerous benefits to Cao Ngạn Thermal Power Company - TKV. Through the integration of monitoring, recording, anomaly detection, and digital signatures, the company has enhanced operational efficiency, reduced risks, and strengthened effectiveness in production management. The Operational Logbook has proven to be a powerful and reliable tool in maximizing performance and safety during production operations. Cao Ngạn Thermal Power Company - TKV has successfully utilized this solution, and we sincerely hope it becomes a dependable choice for many other businesses. Please contact us to discover more about the Operational Logbook and how it can support your operations.