In today's energy industry, with the ever-increasing demand for electricity consumption, Cao Ngạn Thermal Power Company - TKV plays an irreplaceable role in providing reliable electrical power to the community and various industries. To ensure continuous and stable energy production operations, we focus on deploying the Maintenance and Repair Module - a practical tool to improve performance and optimize the production system.

Features of the Maintenance and Repair Module:

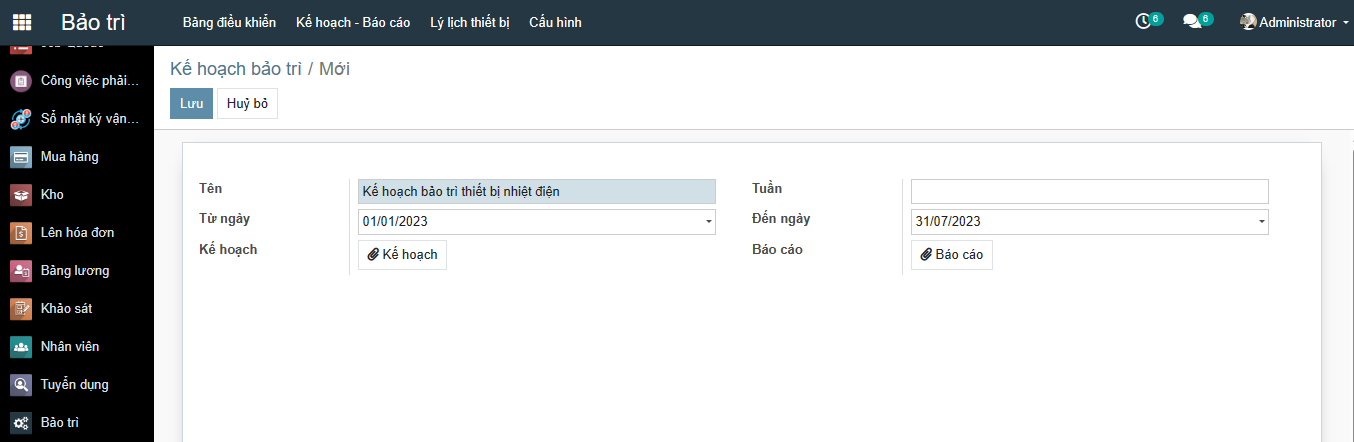

Scheduled Maintenance Planning: The module supports the company in establishing regular maintenance schedules for critical equipment and systems. Detailed and meticulous planning ensures timely maintenance, enhances the regularity of operations, and minimizes unexpected issues.

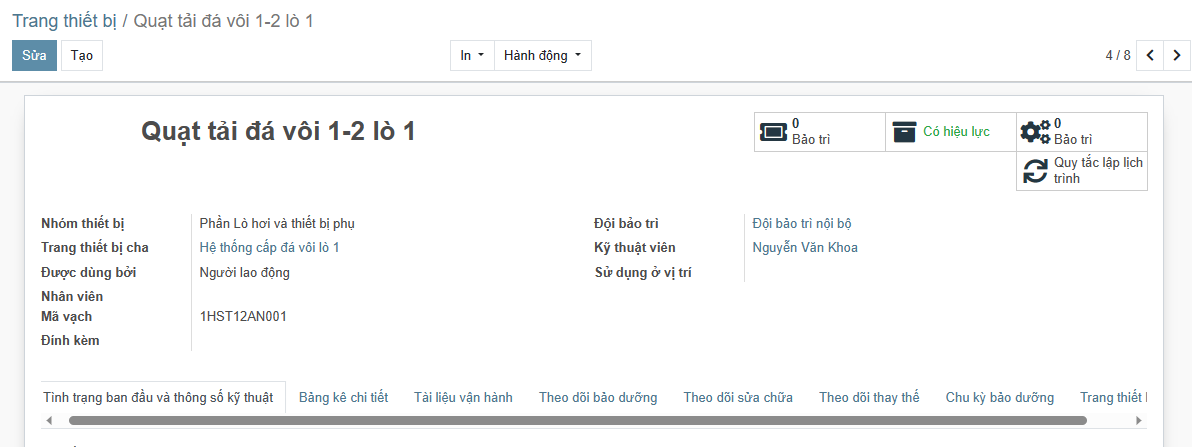

Maintenance Information Management: The module provides a comprehensive information management system, including maintenance history, fault reports, regular repair logs, and current equipment status. Efficient information management enables us to assess the effectiveness of maintenance activities and propose valuable improvements.

Equipment Performance Monitoring: The module equips us with monitoring tools to track the performance of equipment and machinery in the energy production system. This enables timely detection of any anomalies and allows proactive repair intervention before they lead to disruptions in production.

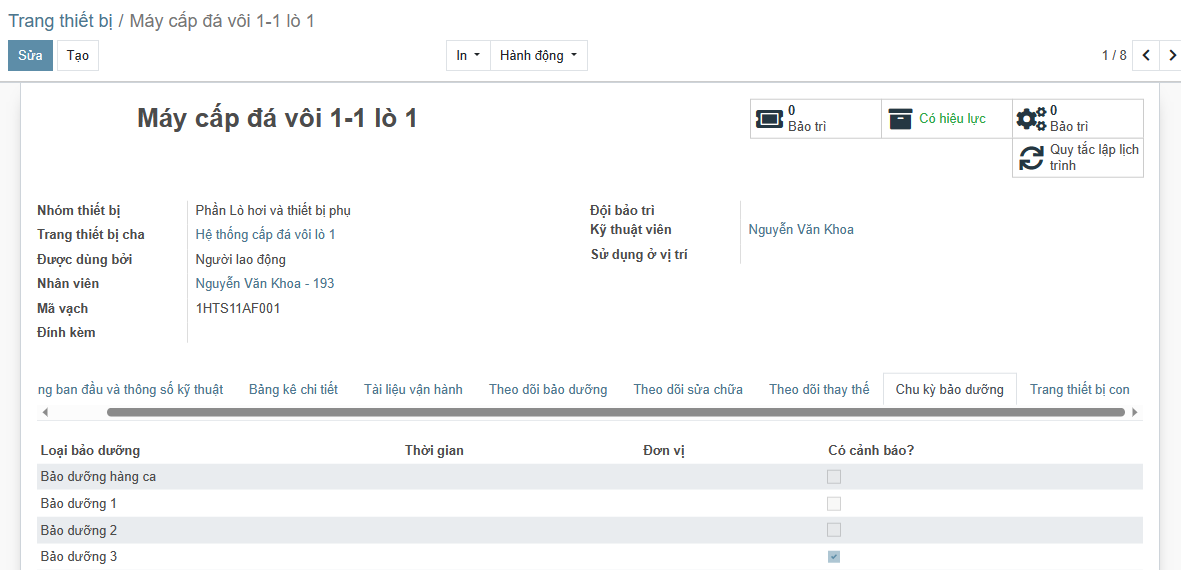

Early Warning System: The module automatically provides early warning alerts to identify and analyze potential issues before they escalate into major concerns. This helps us implement timely corrective actions, reduce downtime, and ensure system stability.

Optimal Maintenance Scheduling: The module assists in determining the appropriate time and frequency for maintenance of each piece of equipment. This optimization helps reduce unnecessary waiting time and saves maintenance costs.

Spare Parts Forecasting Support: The module provides tools to predict spare parts and component demands during maintenance. Maintaining suitable inventory levels helps us avoid shortages and unnecessary waste.

To deploy the Maintenance and Repair Module and maximize its benefits for the energy production system, we invite interested units, companies, and organizations seeking to optimize maintenance processes, enhance operational efficiency, and ensure system stability to contact us today.

We are committed to delivering a tailored Maintenance and Repair Module solution that meets the specific needs and requirements of each customer. Our professional and experienced team will provide consultation and support from implementation to user training and ongoing maintenance.

Let's work together to build a sustainable and reliable energy production system for our community and our planet.

Contact Information:

Website: www.erptoancau.com

Email: erptoancau@gmail.com

Phone: +(084)943730142

Thank you for your interest and contribution to creating a future of clean, efficient, and sustainable energy for our community and our planet!

Implementing the Maintenance and Repair Module for Cao Ngạn Thermal Power Company - TKV: Enhancing Efficiency and Sustainability for Energy Production System

24 July, 2023

bởi

| No comments yet

Hoàng Hồng Vân

Sign in to leave a comment