I. What is the concept of Odoo Manufacturing?

Odoo Manufacturing is part of the Odoo extended business management system, developed to support the management and optimization of production processes in businesses. With Odoo Manufacturing, businesses can organize and operate production activities effectively, from managing production schedules to managing materials, human resources and quality control processes.

II. Benefits when businesses use Odoo Manufacturing

Improve supply chain management

Odoo's supply chain management module can help manufacturers optimize their supply chains by providing real-time information on inventory levels, orders, and orders. This can help businesses make informed decisions about production, purchasing and delivery.

Advanced production planning and scheduling

Odoo Manufacturing allows manufacturers to create orders, plan schedules, and track progress in real time. This can help businesses manage production processes more efficiently, reduce lead times and improve delivery times.

Proper inventory management

With Odoo Manufacturing, businesses can monitor their inventory levels, automatically reorder, and track warehouse movements in real time. This can help businesses avoid stockouts, reduce inventory holding costs, and improve order fulfillment rates..

Better quality control

Odoo Manufacturing's quality management module helps businesses implement quality control measures, track quality issues, and analyze root causes to identify and resolve quality issues . This can help companies improve product quality, reduce waste and improve customer satisfaction.

Use resources effectively

Odoo Manufacturing manages resources more effectively by tracking resource usage, scheduling maintenance, and identifying production bottlenecks. This can help companies optimize resource usage, reduce downtime and improve productivity.

III. Key features in Odoo Manufacturing

1. Product lifecycle management (PLM)

Product lifecycle management (PLM) is a term that refers to the management of products throughout their life cycle. Activities related to product lifecycle management, such as planning and building production processes, will be performed in Odoo Manufacturing.

Technical aspects are planned in advance

Technical drawings are stored in the Documentation module

Prepare a bill of materials including drawings

Keep track of product and ECO versions and corresponding documentation. Consolidate different ECOs using the same BoM bill of materials.

2. Dedicated maintenance module

With a dedicated maintenance management module, you can manage the maintenance of your production equipment as well as the maintenance of your company's equipment, including preventive and corrective maintenance activities.

Preventative maintenance according to KPI indicators and predictive maintenance should be performed

Corrective Maintenance: Enable corrective maintenance directly from the central dashboard

Scheduled maintenance activities

Preventive maintenance schedules are automated

Create a maintenance request

In addition, repair activities for defective products due to the manufacturing process will also be performed at Odoo Manufacturing.

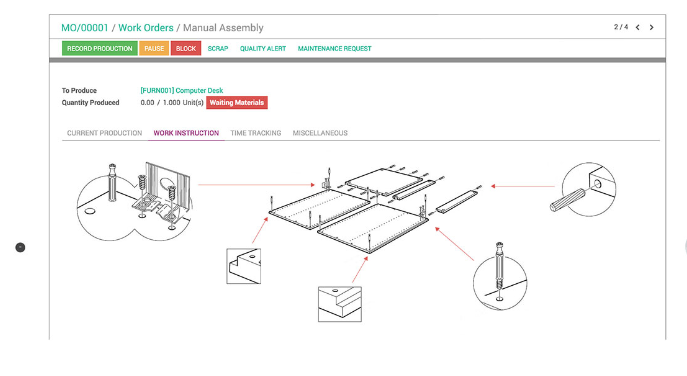

3. Control production area

Tablets: Set up tablets in each production area to control work

Register production, scan product, batch or serial number

Display the roster in the production area with instructions for users

Reject products, create quality alerts, perform inspections right from the production floor.

Use alerts to display changes or quality checks to operators.

Identify the different steps in a work order and link them to a spreadsheet: product scanning, photography, quality control,...

4. Production quality management

In product manufacturing operations, this module is responsible for quality inspection and necessary quality control aspects.

Automate the quality inspection process for the production department

Easily deploy quality inspection plans

Quality alerts using kanban view with quality alerts.

5. Planning and management tools

Create and manage work plans

Manage raw materials list

Plan preventative maintenance

Production orders: Manage products in assembly lines or manual assembly

Use barcodes to speed up production: scan product batch or serial numbers, start/pause/stop timers, trigger a maintenance request, move to the next step,...

6. Warehouse management

Use ordering rules, minimum inventory rules, or master production schedules to automate purchasing processes; Schedule calculations. Use routing, constraints and lead times to optimize inventory levels and avoid shortages.

7. Report

Receive complete reporting and tracking of ingredients used in the manufacturing process and reports including:

Report orders from manufacturing industry

Report on production orders

Report on the overall performance of the device

Based on the cost of components and operating costs (labor or materials) to track work order costs

Analyze capacity of production areas, yield loss and monitor overall equipment performance (OEE)

Address: 16/117 Nguyen Son, Gia Thuy Ward, Long Bien District, Hanoi, Vietnam

Phone: +(084)943730142

Email: erptoancau@gmail.com

Website: https://erptoancau.com